Credit:Biovision-Infonet

Honey is harvested at the end of a flowering season. It can be considered more fair to the bees to harvest it a bit before, especially in hives where the whole comb is removed, to allow the bees to re-establish the comb and collect more honey for themselves. Under all circumstances, the beekeeper selects those combs which contain ripe honey, covered with a fine layer of white beeswax. These combs are usually the outer ones. Combs containing any pollen or brood should be left undisturbed. Honey will keep a long time if it is clean and sealed in an airtight container, but will deteriorate rapidly and ferment if it has absorbed water. Preventing this from happening is crucial in honey harvesting.

The principal idea in harvesting honey is identifying the comb with ripe honey, free it of bees and take it away for processing. This entails shaking the bees off the combs, young bees normally cling on the comb therefore they are brushed off using a bee brush.

Reasons to increase honey quality through processing

– Processing eliminates all foreign particles and dirt from honey.

– Warming (not over 40degC) honey during processing destroys yeast which cause fermentation (but only if the honey contains juice from crushed bees or bee larvae). (Do not overheat the honey on the open fire)

– Warming honey delays crystallisation.

– Processing adds value and therefore honey fetches more money.

Honey extraction

The honey comb can be simply cut into pieces and sold as fresh cut comb honey. Alternatively, the honey and comb can be separated and sold as fresh honey and beeswax. It is important when processing honey to remember that it is hygroscopic i.e. will absorb moisture, so all honey processing equipment must be perfectly dry.

Squeezing the honey out by hand

The most common traditional methods of honey extraction are squeezing or melting the combs. Melting the honeycomb is wasteful and makes the quality of both the wax and the honey inferior; it should be avoided. If your quantity of honey or financial resources are small, then squeezing the honey out by hand is probably the most viable option. Honey combs should be scraped with a knife or fork on both sides to open the capping of the cells, then left to drain through a fine dry sterilized muslin cloth into a clean container. Make sure there are no crushed bees or bee larvae among the honey combs, as this reduces the quality.

Honey combs cut from a KTBH or Log hive can be strained with a straining net as illustrated

The honey extracted by this method will have to be strained through several increasingly finer meshes to remove any bits of wax or debris, ending with something like muslin cloth. It is very important that this procedure be carried out hygienically, and that the honey is not left exposed to the air, where it will pick up moisture and deteriorate.

With a Langstroth hive one can use the bee escape (clearer board). Fix the bee escape between the brood box and the super. After 24-48 hrs all the bees will be cleared off the honey supers. The supers can then be removed for honey extraction. Ensure the clearer board is removed and the supers replaced with empty ones.

Extractor

(c) S. Fontana, Biovision

(c) S. Fontana, Biovision

Honey storage

(c) Practical Action

Store the honey in glass jars or plastics buckets with well-sealed lids or in a metal container which is coated with a layer of food grade varnish. In humid areas the honey must be stored in airtight containers to prevent water absorption and consequent fermentation within a few days after extraction. If you want to sell your honey you should add a label describing the source of the honey (for example sunflower, mixed blossom, tree honey), the country and district it was produced in, the net weight and your name and address.

Beeswax processing

The comb from which bees build their nest is made of beeswax. After the honey has been removed from the combs, the beeswax has to be extracted. This is to save it from destruction from the wax moth.

Put the wax into an open container which sits in a water bath. Bring the water to a boil and skim off any debris floating on top. Afterwards pour the liquid wax through a fine filter for a final clean.

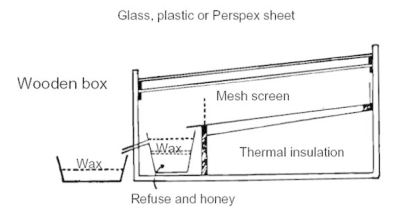

Another option for processing the wax is a solar wax melter. This appliance is easy to make and consists of a wooden box with a galvanised metal shelf with a spout, a bowl or container that sits under the spout, and a glass or plastic cover. When placed in the sun the temperature inside the box will melt down a comb and the wax will flow into a container inside the box. Any honey that was left in the combs will sink to the bottom; it is usually used for cooking or beer making as its taste is spoiled somewhat by this process.

Beeswax does not deteriorate with age and therefore beekeepers often save their scraps of beeswax until they have a sufficiently large amount to sell. Many beekeepers still discard beeswax, unaware of its value. Beeswax is a valuable commodity with many uses in traditional societies: it is used in the lost-wax method of brass casting, as a waterproofing agent for strengthening leather and cotton strings, in batik, in the manufacture of candles, for making polish, and in various hair and skin ointments. Beeswax is also in demand on the world market. Beeswax for export should be clean and have been re-heated as little as possible.

Before you can put the beeswax on the shelf for the purpose of selling it you must prepare it well having the following general requirements in mind.

– The colour of beeswax varies from whitish yellow to yellowish brown. This will depend on the type of combs one used when making the beeswax.

– Beeswax should be free from organic matters such as bees, brood, debris, sand or any other undesirable materials.

– It should not be adulterated by blending it with other types of wax such as paraffin wax, synthetic wax or any types of oil or fat (animal or vegetable).

Uses of wax

(c) Mette Vaarst, Biovision

Once beeswax has been extracted from the combs, the beeswax cake maybe remoulded into desired shape. There is a high demand for beeswax for making candles.

Procedure:

Melt the piece of beeswax using a water-bath (indirectly), quickly pass the molten wax through a clean cotton cloth, the desired mould (smeared with detergent solution) should be ready to receive this wax. Let it cool for several hours. Remove and clean the beeswax cake with a soft damp cotton cloth.

Value addition for bee products

Honey is a major ingredient used in the preparation of various products that are of benefit to the human body. It is also used as a sweetener in various recipes.