Credits:Biovision-Infonet

Good, efficient housing makes management easier and helps the farmer to successfully rear 85 % or more of all the live born piglets to market weight. Pigs at different stages of growth need different environments (temperatures) rations and must have outdoor access all the time. Growing and reproducing pigs must be protected against high temperatures. The houses must therefore be built in such a way that the pigs are protected against extreme temperatures and other bad weather conditions such as cold winds and continuous rain.

Types of housing

Pig housing will depend on the rearing system.

In free-range system or a tethered system where pigs are on a rope, no housing is provided apart from different forms of night shelters, e.g. a roofed coral or a coral under a leave roof.

If pigs are tethered, look carefully after that the rope does not hurt them, and that they have everything which they need, within reach, and can be in shade if needed.

(c) S. Gikonyo, Kenya

In improved free range system, pigs are confined within a fenced area using strong wire netting or local materials such as bamboo. Shade is essential and is usually provided by simple roofs constructed or use of tree shades

(c) S. Gikonyo, Kenya

Semi-intensive: Pigs are kept in houses confined to a limited space. Feed mainly fresh water and fodder have to be brought to the pigs. A roof is provided, the walls commonly made of timber off cuts or old iron sheets. If this is partly outdoor, the pigs have rooting material and space enough, this can probably be acceptable in organic farming

(c) S. Gikonyo, Kenya

Intensive pig keeping: Intensive pig keeping: Pigs are kept in complete confinement; fatteners, boars and sows with their litters in separate units. Management is usually high and higher numbers of pigs are reared. This type of system is not allowed as organic agriculture and should not be encouraged also for conventional farming.

(c) S. Gikonyo, Kenya

How to keep sows and pigs?

In organic pig and sow herds, confinement of animals is not allowed for shorter or longer periods. According to the principles, animals should have access to natural behavior, and exercise is a natural need. Especially, sows around farrowing needs to perform natural behavior, e.g. nest building. However, keeping them in pigsties indoor in combination with outdoor runs is possible, and keeping weaned pigs in pigsties with access to an outdoor run is also possible.

Certain guidelines can be given, no matter which system is chosen

- The number of live piglets at the age of weaning will increase, if they are born in secure and healthy surroundings.

- Controlling the health of the pigs is easier if they are kept in a yard. They should in all cases be easy to overview, because that gives the best chance of identifying problems at an early stage,

- A high level of hygiene should be maintained, no matter whether they are indoor or outdoor. The pen should be cleaned and kept clean, and the animals should preferably have soft bedding material,

- Feeding routines should be carefully controlled, especially in cases where individual feeding may be necessary.

- Manure can easily be collected and used for fertilizing land from pigsties.

- If possible to integrate pigs into the crop rotation system, use can be made both of their manure and their rooting behavior in cases where management is needed of a field after harvest and before the next planting.

- Protection against theft should always be considered, either by taking them indoor during night, and by placing them in places which discourage thieves to look for them.

The following are basic requirements that a pig house should meet to ensure increased productivity and profitability of a pig enterprise:

- The pigsty should be comfortable for the pigs: good ventilation and ample shade, no overheating, no smells, free from draughts and no dampness.

- If the pig is exposed to direct sunshine, there should be possibility for mud baths.

- Floor should be kept dry and must be rough to avoid pigs from falling and therefore being unable to move in the pen freely

- The floor should be concrete or wood since pigs have the tendency to dig into the ground thus making it difficult to clean and increasing the rate of parasitic infestation to pigs.

- The house should have dunging area at the rear and feed trough and water trough in front. It should have a slope to allow free drainage.

- The pens should not be near the dwelling houses or below the wind because of smells and flies.

- To minimize transfer of disease animals of the same age should be housed as close as possible next to each other and the wind flow should be from the direction of the youngest to the older animals.

- The costs of construction the pigsty should fit the pig production system. Cheap, readily available and durable materials should be used for house construction to reduce cost. The house however should have all the essential parts.

Location of the Pig House

- A pig house should be sited away from walls of other buildings to allow air circulation The area should be well drained.

- The building should face east – west to avoid direct sun rays or have shade from trees.

- The pig house should be located such that the wind flow is away from the residential premises.

- It can be convenient to place it near the family house, to keep it close and thereby prevent theft.

In hot climates buildings should be of the open type (half walls) which facilitates surveillance, promotes excellent ventilation and are inexpensive. It is difficult to control heat stress in fully enclosed buildings in the tropics.

There are a number of designs according to their use for weaner pig production, fattening pigs or a combination of breeding and fattening.

The decision as to which option to follow is based on the general organization of the local pig industry.

Recommended Materials

Floors

Floors must be impermeable, and easily cleaned with a shovel and brush as well as with pressure washers. This allows eggs of parasites to be removed and prevents spread of infection. Floors of hardened soil (murram) are not appropriate because pigs grub the soil. Special care should be taken to make the surface of floors non-slippery where concrete or wooden floors are made. Wooden floors are warm but have specific problems such as decay, insect attack and chewing by pigs. Hardwood must therefore be used, making them very expensive. Concrete floors are tough and long lasting if well made; easy to clean and reasonably priced. They are also cool, which is beneficial in hot climates. Floors need to have a sufficient slope of about 3% or slightly steeper which allows adequate drainage.

Bedding

In organic farms, bedding material should be provided for the pigs, no matter the age, such as rice straw, sawdust, dry leaves etc. If using plants, make sure that they are not poisonous for pigs. Pigs have a habit of finely chewing their bedding litter and will swallow part of it. The leaves of the Wonder Oil Plant (Castor Bean – Ricinus communis) for example should not be used. Bedding material should be changed regularly to keep the pen clean and to avoid any parasite build-up.

NB. The mixture of bedding with dung and urine makes an excellent fertilizer for the fields, and is especially valuable if converted into compost.

(c) S. Gikonyo, Kenya

Walls

Walls should be erected over a foundation of sufficient strength. They can be constructed of brick, stone, mud or bamboo or any other material suitable for the locality and climate. Stone or brick walls are costly but durable and hygienic. Bamboo and mud walls are economical and useful but are temporary and hard to keep hygienic. Walls supporting the roof and wall partitions with which the pigs come in direct contact must be strong and materials such as brick, stone, or cement concrete may be best at least for the lower parts of the walls.

Vertical barriers

Partitions within piggeries (90cm, except for boars, which should be 110cm), which allow different categories of animal to be separated, should be provided with gaps to allow good circulation of air at pig height. In order to prevent pigs from escaping, spaces between planks must be small at the bottom.

In order to avoid damage from pushing, posts must be solid and planks nailed from inside. Partitions of reinforced concrete 10 cm thick are also possible but these are more expensive. These solid partitions should be limited to transverse sections separating different areas of the building but should not be for longitudinal partitions as this would limit air flow at ground level.

For the outer wall special wire netting or gates are used effectively. For the inner walls, if the piggery is two-rowed, a system of rails or flexible wire above the trough is preferable. This allows pigs in pens opposite to see each other. Older gilts and dry sows come on heat faster when they see the boar.

Gates

These should consist of 200 mm planks, built with reinforcement in the shape of a ‘Z’ on the inside. A width of 60 cm is sufficient even for the biggest animals. They should be attached with particularly strong fittings to withstand pigs rubbing against them. The latches should be of the locking type that is not opened if the door is shaken. A latch is moved much more easily than a bolt.

Roofs

The roof should be light, strong, durable, weather-proof, a bad conductor of heat and free from tendencies to condense moisture inside. They must ensure maximum shade and should extend down almost to ground level to reduce penetration of oblique sun rays and entry of rain when blown by the wind. Roofs can be made of thatch, aluminum, galvanized iron, tiles, wood or bamboo. Thatch, bamboo and galvanised iron roofs are the most recommended. Recycled sheets certainly are still of use for makeshift piggeries.

Feeders

A considerable amount of care must be taken with feeders to avoid all feed wastage. In the first place, whatever the type of piggery, they must be fixed. A mobile feeder is always up-ended and the food soiled, trampled and wasted. As a consequence, experience has shown that feeding on the ground is not appropriate. In hot climates pigs occupy most of the pen area and tend to soil the entire floor area, particularly at high stocking densities. Wastage of food seems to be higher.

Feeding troughs must be easily cleaned, even if pigs themselves do this to an extent. The internal surface must be smooth and without sharp angles. The depth must be sufficient (20 cm) such that the food only occupies the bottom and cannot be flicked out.

Finally, they should not be used as a wallow: pigs have the habit of lying in feed troughs. Therefore, subdividing the trough transversely with metal rods (10 mm preferably) every 40 cm, if it is to be used by many animals, is recommended. This has the advantage of allocating places from the moment of feeding.

The trough may be wooden and fixed to walls with removable bolts. However, if it is to be used by more than two animals it must be replaced by one made from cement, which meets all necessary requirements. It should be placed along the service wall to aid distribution of food. Cement troughs should have a round hole in the bottom with a bung placed from the outside; this will allow them to be cleaned with water.

If a basal diet is fed ad libitum, this may be offered effectively from wooden hoppers which may contain maize, dry cassava chips, etc. This ensures that animals do not go without food, and makes distribution easier. These hoppers may be made readily from wood. There are advantages in surrounding the bottom corners of the base with iron to prevent its rapid decay.

The animals must be able to reach the feed easily. The feed level must be kept as low as possible to avoid feed wastage.

(c) S. Gikonyo, Kenya

Watering

Pigs in hot climates, particularly lactating sows, must be given plenty of water, which should be continuous. When feeding under restricted conditions, the troughs may be used as drinkers between meals.

For large piggeries where a running water supply is available, automatic drinkers should be used. Water within bowl/drinkers is soiled regularly and pigs themselves often compound the situation. Nipple or valve drinkers are preferable. These are placed at a height of 60 cm with an additional step of 30 cm placed beneath them if they are to be used by piglets. These drinkers have several advantages; the water drunk is always clean; spillage is minimized and costs are reduced. Their use is governed to an extent, however, by stability of water pressure. Their control is not standard and becomes impossible under situations where pressure is subject to wide variations. However, low pressure can be maintained by using a reducing valve or a water storage tank.

(c) S. Gikonyo, Kenya

(c) S. Gikonyo, Kenya

| Sows | Fatteners | Weaners | Boar | |

| Trough Length (cm) | 40 | 35 | 20 | – |

| Floor Space (m2) | 1.2 | 1 | 0.5 | 2.5 x 3 |

| Dung area (length in m) | 1-1.5 | – | – | – |

Lactating sows will require a creep area (1 square metre) or special pens fitted with guardrails /hurdles or supplied with a farrowing crate.

Space

The housing system should allow all pigs to lie down comfortably at the same time on a soft surface with bedding material.

- The lowest bar of the rails in the farrowing area must be 23 cm above the floor

- Trough depth 20 cm

Special Housing Requirements

Pens for Sows with Piglets

Special accommodation for the sow with piglets is essential to avoid high mortality among the piglets. Separate areas for both the sow and piglets are recommended by many. Not all sows are naturally attentive (good mothers), so special management is needed to avoid crushing of piglets. Some breeds also make sows very long and particularly heavy on the hind part, which makes it difficult for them to lay down quietly and under full control. The risk of crushing is consequently very high.

Using guard rails and hurdles and providing a creep area where the piglets have a warm nest away from the sow can reduce mortality. At the same time, it’s important to have good access to the pen and be able to feed and handle the animals. Several designs have been developed to meet these basic requirements.

(c) S. Gikonyo, Kenya

Constructing a creep for the piglets

You may provide the piglets with a special safe place called a ‘creep area’ in the sow’s pen where the piglets can creep in for warmth and safety. The sow’s pen can be divided into two parts, the bigger area for the sow and the smaller area (1 square metre) for the piglets. The opening to the creep area should be small enough to only allow piglets inside. A heating lamp or charcoal burner raised on a firmly placed block should be put in the creep area to provide extra warmth. In very cold weather, the creep area can also be covered with empty grain bags in order to trap heat inside the creep area. The piglets will need the extra heat until they are 2-4 weeks old depending on where they are reared. When the piglets are cold they will tend to bundle together. The piglets nearly always prefer the protective ‘creep’ rather than lying against the sow. The creep area can be used for introduction of a little feed for the piglets as early as the 7th day of age. This helps the piglets to get used to eating other feed in readiness for the time of weaning.

A combination of a farrowing and rearing pen, the sow is confined in the sow area (0.7×2.5metres) leaving two creep areas on either side (0.8×2.5 metres). A run of 1.5 metres is provided at the back. If this type of confined pen is combined with exercise areas or outdoor runs, they can probably be used in organic herds. Otherwise, they are prohibited in organic farms.

(c) S. Gikonyo, Kenya

Restrictive Farrowing /Rearing pens – are not prohibited in organic farming and should be discouraged

Restrictive farrowing rearing pens for intensive production are also available but cost is prohibitive, and they are not suitable for organic production. Organic management favours that animals should be allowed natural behavior also during farrowing, and this is absolutely not possible in these pens, which force the sow to stand, lay or sit with her head in one direction. In large parts of the world it is forbidden because it does not allow exercise and all animals should be allowed regular exercise. (In these systems the sow is confined in a space of 65 cm by the two sets of hurdles. A creep area in front (50 cm by 80 cm) is provided with heating source to provide warmth to the piglets. The floor is made up of plastic slates for easy manure handling). In other words, if the use of these pens is not explicitly forbidden according to national standards, they should be discouraged.

Housing of Dry Sows/Pregnant Sows

Dry and pregnant sows can be housed in different ways. On smallholder farms the dry sows can be in one group, in a pen with an outdoor run. For group housing, a maximum of 3-4 sows should be kept in each pen of 9-10 suare metres.

On small farms it is difficult to form uniform groups in terms of age, pregnancy stage, size etc. It will be a great advantage to form groups of animals with the same feed requirements. Otherwise, individual feeding should be explored, so that any saw gets the ration it needs.

At weaning, sows have to be moved from the farrowing pen to another pen (preferably another compartment or building). To stimulate them to coming on heat, sow contact with the boar is essential. This could be achieved by keeping the sow in a pen next to the boars’ pen. Where land is available, sows can also be kept partly or completely out doors. Sows kept in paddocks should be rotated regularly to avoid parasite problems and to keep the pasture in good shape.

(c) S. Gikonyo, Kenya

Housing of weaned pigs

At weaning, the sow should be taken away from piglets. The weaned pigs can be taken to another pen after some time. It is good for them to not have all the changes at once. Weaners of the same age can be kept together. Pens for newly weaned pigs can be simple as long as a lot of attention is given to hygienic condition to avoid scour and worm infestation. Organic weaned pigs should have an outdoor run.

Housing of Boars

The basic requirements for environmental comfort of boars and sows are similar. It has been observed that excessively high temperatures negatively affect the quality of the boar’s semen. Thus care should be taken to ensure that the boar is not subjected to extreme hot or cold conditions. A minimum area of 2.50 x 3.00 square metres is required. When a boar has a mate, the pen area should be 8 – 9 square metres. A separate area can be created (4.00 x 4.00 square metres) where the mating can take place. The pen or service area must be kept dry and free from obstacles.

Gilts

Gilts from three months till service (8 months) can be kept in pens which are similar to fattener pens. Afterwards they should be kept in a different pen with a different floor space. It is important to have enough spaces available for gilts. Up to 8 gilts can be kept in one pen of 3 x 3m.

Housing of Fatteners

Housing of fatteners

(c) S. Gikonyo, Kenya

In designing the kind of fattener house, the following must be taken into consideration:

- Construction with outdoor area that promotes animal welfare, with shade and rain-protection

- Construction preventing feed losses and saving labour

- Construction price in relation to the earnings of the fatteners.

NOTE:

- A limited number of fatteners per pen has a positive effect on the productivity (high ADG)

- Not more than 8-12 fatteners should be kept in a single pen (3 x 3 m).

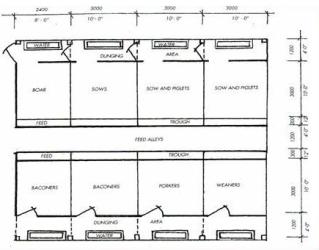

Layout of the piggery

(c) S. Gikonyo, Kenya

A modest piggery may be composed of adjacent pens in one row with a roof extending over them so that exposure of pigs to sunlight is minimised. The dunging area should be on the side where the door is with the feeder on the other side in the shelter of the roof. Piggeries consisting of more than six pens should be built in two rows to avoid the building being too long. This is to enhance air circulation.

The layout of the building should be arranged to reduce traveling distances to a minimum. Pens should be positioned as in a piggery with only one row and opposite each other with feeders facing each other. The central passage should be 1.5 m wide to allow wheelbarrows and feed trolleys/wagons to pass. It should not be too wide otherwise, the cost of covering the area will be high.

Stores must be situated in such a way that feed trolleys/ wheel barrows have good access to passages and that walking lines are as short as possible.

Pig House Construction Planning

Before building a pig house, one must know the number of places or pens needed for lactating sows, dry and pregnant sows, replacement stock, boars and fatteners. These places can only be calculated after a farmer has decided about the following starting points:

- The number of sows on the farm.

- The expected number of farrowings per sow per year (litter index).

- The division of the farrowings per year (specific season or year round)

- The weaning age.

- What kind of weaner pens the farmer want to use.

- Whether the farmer wants to have a boar or use artificial insemination.

- Whether he selects his own young breeding stock or wants to buy them from outside and at what age.

- What type of housing for dry and pregnant sows (group or individual).

- The expected selling rate.

- The expected growth of the piglets.

- Days needed for disinfection and cleaning.

- The expected growth for the fatteners.

- The number of animals per pen.

(c) S. Gikonyo, Kenya

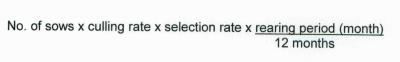

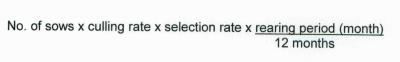

Formulas to Calculate the Number of Places or Pens

The number of places or pens, for a farm with farrowing saws year round, can be calculated as follows:

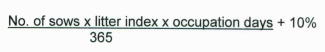

Farrowing rearing pens

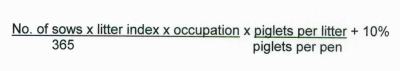

Weaner pens

An allowance of 10% is given for longer gestation periods, lower growth of piglets and other irregularities in the reproduction cycle.

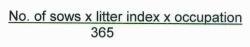

Places for dry and pregnant sows

(1/3 dry sow till 1 month after service; 2/3 pregnant sows)

Places for replacement stock

Number of pens for boars

A teaser boar is necessary when A.I. is used. When natural service is used, one boar for every 15 sows must be considered.

Place for fatteners (closed farm)

Examples

On the example farm: There are 5 sows, piglets are weaned at 7 weeks and moved to the weaner pens 5 weeks later weighing 20 kg and housed 8 per pen, 3 days of cleaning weaner pens.

The sows are kept in groups of 5. Litter index 1.7, while for the occupation days one week is taken for acclimatization the sow before farrowing and 3 days for cleaning and disinfection.

Number of farrowing rearing pens

5 * 1.7 * (49+10) + 0.137 = 1.5 pen (= 2 pens)

365

Number of places for dry and pregnant sows

The number of days from weaning to service is 6 (fixed). After calculation we arrive at 45 lost days.

5 * 1.7 * 159 = 3.7 places (dry sows can be in one group outside)

365

(Cycle is 365/ 1.7 = 215 days. 215 – 49 – 7 = 159 days occupation)

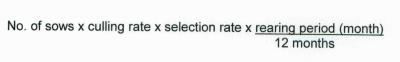

Places for gilts

The selling percentage is 40% and only 2 from the 3 gilts selected at an age of 3 months will come in production. The gilts stay in the group gilt-pen till service.

5 * 0.4 * (3/2) * (8 -3)/12 = 1.25 places

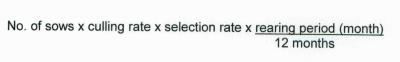

Places for fatteners

Places needed

(5 * 1.7 * 7.3)/ 2.37- 6 = 25.6

In summary on a farm with 5 sows and the offspring for fattening there are the following places and pens:

| Category | No of places | No. of pens |

| Rearing sows | 1.5 | 2 |

| Weaners | 7.3 | 1 |

| Dry and pregnant sows | 3.7 | 2 |

| Gilts( Replacement) | 1.3 | 1 |

| Boars | 1 | 1 |

| Fatteners | 25.6 | 3.2 |

The expected daily gain is 500 grams and the growing period is from 23 kg till 93 kg live weight. First the number of rounds has to be calculated: growth (93 – 23 kg) is 70 kg. Daily gain 500 gram so it takes 70 / 0.5 = 140 days to grow to slaughter. An allowance of 10% has to be added (slow growers, extra occupation and cleaning) 140 + 10% total occupation days. This means 365 / 154 = 2.37 rounds per year.