Credits:Biovision-Infonet

A hive is the box or some other container where bees live. In Kenya there are three types of hives:

- Traditional Hives

- Kenya Top Bar Hives (KTBH)

- Frame hives

Traditional Hives (Log Hives)

(c) A. Bruntse, Biovision

Log hives and other traditional hives contribute to about 80% of Kenya’s honey production. They are estimated to number almost 1.5 million countrywide, and provide a livelihood to many especially in arid and semi-arid lands. Log hives are cheap but difficult to harvest.

Traditional hives are largely considered as no more than man-made cavities in which bees live. They come in all forms as hollowed-out logs, discarded metal cans or drums, clay pots, wooden boxes, baskets of straw, bamboo and many others. Honeybees attach combs directly on the upper surfaces of the hive and usually to the sides.

Advantages

– Materials for construction are readily available and are cheap in most cases free

– Beeswax and propolis production is relatively high

– Traditional hives and methods of working with them are established

Disadvantages

– It is impossible to remove or replace combs. This makes examination and harvesting difficult.

– Swarming is often common due to limited space.

– Brood is often lost during harvesting.

– Honey production is limited.

– Honey quality is usually low (mixed with pollen, brood and ashes).

– Many adult bees are usually killed during harvesting. This must absolutely be regarded as critical in organic agriculture, as it is very unfair to the bees.

– There is usually a lot of colony disturbance during harvesting which in most cases causes absconding. This is – like above – very unfair to the bees, and therefore not recommendable in an organic farm.

Kenya Top Bar Hives (KTBH)

(c) P. Luethi, Biovision

(c) Apiconsult

Usually the bees attach their combs to the bars but not to the side of the hive, since the walls are slanted at an angle of at least 14deg. This allows lifting out of the combs for examination. The bees attach their combs to the bars which can be lifted out of the hive for examination.

In Kenya, the Kenya Top Bar hive was designed and adopted in 1971. Other hives, such the modified African Long Hive and the Langstroth Hive, have since been introduced. However, the Kenya Top Bar Hive remains the most dominant and most widely used due to its simplicity, affordable price and advantages.

Advantages

– Only one critical dimension in construction i.e the top bars. Other measurements are not too critical, thus hives can be made with simple tools from relatively cheap local materials, including concrete.

– Every comb is accessible without removing the others. This causes less disturbance to the colony and greatly reduces the number of bees flying around when the hive is open.

– The brood can be inspected easily, which gives the beekeeper real control over the management of the hive.

– The beekeeper can judge the exact time when combs are ready for honey harvesting without disturbing the brood.

– The honey is of higher quality as the combs can be selected to be free of pollen and brood.

– The top-bar hive makes it possible to gather good quality beeswax for which there is always a ready market.

– The better management techniques promoted by these hives help preserve and increase the bee population and leads to increased pollination and production of honey and wax.

Major disadvantage

– Combs are cut during harvesting, and bees have to make new combs after each harvest. This leaves the bee-keeper with considerations of making a ‘fair share’ with the bees, and harvest at time of flowering, which still allow the bees to build up combs and honey to times with more scarcity in the surroundings in terms of honey and nectar.

(c) Thomas Carroll, Kenya (2006)

(c) Thomas Carroll, Kenya (2006)

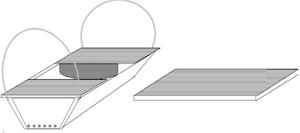

Frame Hives (FH): Example, Langstroth Hives

(c) P. Luethi, Biovision

(c) AIRC, Kenya

(c) Thomas Carroll, Kenya (2006)

This hive is named after its inventor L.L. Langstroth. The hive consists of precision-made rectangular boxes which fit one on top of the other. It has at least two boxes (supers) with the lower chamber called the brood chamber.

Between the brood chamber and the super sometimes a queen excluder is placed. It limits egg laying activity of the queen to the brood chamber only. The wooden frames are “wired” and complemented with a sheet of wax foundation. Each box contains a set of framed combs. During harvesting the frames are removed and put into a extracting machine, which removes the honey leaving the combs intact. The combs are then returned into the hive for reuse by the bees.

Other standard hives exist, besides the Langstroth hives, for example the Dadant hive.

The race of the kept bees, financial means as well as available woodworking equipment are all more important than the dimension of the hive box. However, bee space is critical. Bees require this space between the sides of each frame and the walls of the hive. The bees space for most African Apis mellifera is 6 mm (1/4inch). Without attention to the proper bee space, beekeeping will be difficult, because the bees will be building burr combs.

Advantages

– The wax comb is fixed within a frame facilitating and maximizing harvesting and the added strength means less chance of damage to combs during removal from the hive and extraction.of honey. – The strength of the frame/comb allows the hive to be transported even on rough roads, and so the beekeepers can cash in on the pollination market or move bees to another area when forage is short. In organic agriculture, moving of bees over distances should be kept at a minimum, due to reasons given in the section above about organic agriculture and bee keeping.

– The whole honey supers can be harvested without disturbance of the brood box below. – Standardization of parts makes for much easier large-scale and commercial operation.

– Honey can be extracted by means of a centrifugal extractor and empty combs returned to the hive where they will be reused and refilled. This maximizes the honey harvest.

Disadvantages

– There are few local craftsmen who have the skill, equipment and precision to consistently make parts that fit exactly and are compatible with each other time after time.

– The need to keep a supply of spare frames and supers for use at appropriate times is an expensive investment.

– In order to capitalise on the frames, a centrifugal extractor is essential. This is difficult to make and has to be purchased from a commercial supplier.